XYZ, Inc. notices that one of its suppliers has been failing to achieve on-time delivery, even though XYZ sends it a 6-month projected order forecast every month. The supplier claims that it takes nine months to receive important raw materials, and that this causes the poor delivery performance. Nevertheless, XYZ must continue purchasing from this supplier, as it is a sole supplier. Given this situation, which of following is the BEST course of action for XYZ to take?

A firm is looking to expand to a larger warehouse. Which of the following should be given the GREATEST consideration when determining the new warehouse's environmental impact?

A company that manufactures rubber balls wishes to discontinue production and move into the golf ball industry. Consider the following steps in the disposition of the current inventory of rubber balls:

I. Dispose of the rubber balls per local regulations

II. Sell the rubber balls on the open market

III. Grind up the rubber balls and donate the material for a playground in the community

IV. Work with engineering to determine if the rubber can be used in the new golf ball line

In order to maximize recovery of its investment, which of the following is the BEST order for the application of these steps (from first to last)?

During an inventory review, a supply manager confirms that parts used for the maintenance of equipment sold during the previous year are still being stored in the warehouse. These parts cannot be used on current equipment. Which of the following BEST describes these parts’

A supply manager for a U.S. firm is tasked with negotiating domestic shipping terms. The terms must ensure that the supplier has liability for any damaged products and is responsible for filing any claims with the shipper. The terms must also allow the buying firm to pay the shipper directly for shipping costs. Which of the following will BEST accomplish this objective?

A company finds that tracking demand for products sold at its retail outlets makes forecasting a challenge. Which of the following would be MOST useful in providing rapid updates when dealing with suppliers?

If a shipment has a gross weight of 500 pounds and overall dimensions of 42 inches x 48 inches x 48 inches, what is the density of the shipment (in pounds per cubic foot)?

Analysis of inventory turnover is generally considered part of what status assessment ratio?

Which of the following refers to a procedure whereby data are collected and compared to requirements in order to make an acceptance decision?

A supply manager is part of a ramp-up team for a new product line. The supply manager's role will include finding and evaluating new sources and obtaining commitments to support the volume projected by marketing. In recent campaigns, sales forecasts have been considerably higher than actual demand, and the supply manager wants to minimize the risk of such a situation happening again. Which of the following arguments made by the supply manager will MOST likely influence the team to re-examine product launch expectations?

A company needs 1,000 widgets in Year 1 and projects that it will need 1,200 widgets in Year 2. The Year 1 order cost for widgets is $5, and the Year 1 carrying cost is S4. A recent contract renewal with the company's 3PL warehouse supplier will increase carrying costs in Year 2 to S6. How, if at all, will the Economic Order Quantity (EOQ) be affected?

A company finds that delays and cost overruns are creating problems in its service contracts. To improve this situation, which of the following should the firm do FIRST?

Which of the following is the BEST reason to use Monte Carlo simu-lations to improve a forecast7

A firm hires a new staff member in its warehousing department. As a FIRST step in the training of this employee, the warehouse manager should

Which of the following requires investment recovery action’

A supplier with a previously good performance record has recently been shipping parts with a number of flaws, making them unusable for production. The firm’s supply manager would like to resolve these problems before taking more drastic measures. Which of the following actions should the supply manager take FIRST’

A supply manager is tasked with assisting internal customers in refining their budgets and planning future sourcing. The supply manager works with the firm's marketing director on a budget which includes a large direct mail campaign and the revision of promotional materials for several products.

Six months later, marketing has nearly exhausted the budget due to cost increases in paper and printing, even though the marketing campaign's scope has not changed. Which of the following did the supply manager and marketing director fail to consider?

At the beginning of each year, a large firm’s indirect procurement organization holds a brainstorming session. These sessions produce many great ideas and foster support among the procurement team. However, after a few years, support for the brainstorming sessions begins to diminish, and the projects discussed are pushed aside in order to deal with more pressing issues. In this situation, which of the following would be the BEST course of action to take?

A sourcing manager needs to outsource production in order to meet demand for a specific product. The internal production schedule and forecasted sales have been provided for the next nine months. Internal production follows a level schedule of 4,000 units per month and up to 7,000 units may be stored in inventory. There is no beginning inventory for January. During what month(s) will outsourced production be required to meet forecasted sales?

MonthJanFebMarAprMayJunJulAugSep

Unit Sales3,0003,0004,0001,0009,0005,0004,0003,0005,000

An organization's capital expenditure policies are MOST closely aligned with which of the following types of assets?

A manufacturer is working to standardize high-volume, low-cost hardware components used in its assembly process. The manufacturer wants to transfer some of the risks associated with inventory carrying costs, warehousing costs, and re-stocking costs to the supplier. Which of the following will be MOST useful in accomplishing this goal?

Which of the following is the PRIMARY benefit of project governance?

A manufacturing firm prepares the following materials requirement plan (MRP):

Master Production Schedule

Week123456

Item A101015152020

Relevant Information

ItemItem's ParentItem's Lead TimeItem's Lot SizeItem's Current Inventory

ANone1 weekLFL50

BA2 weeks5010

CB2 weeks5010

Using MRP methodology, how much of Item B should be ordered, and when should it be ordered7

A supply manager learns that parts used in manufacturing are arriving scratched and must be polished before use, thereby hampering production. Sending the parts back to the supplier is not an option, as they are needed to meet increased demand. Which of the following will be MOST helpful in resolving this problem?

GHI, Inc. is a U.S.-based company with an expanding product line. GHI widens its sourcing of components to global suppliers, including suppliers in countries which are not included in trading blocs or bilateral agreements with the United States. Compliance with which of the following will MOST likely reduce GHI's administrative burden of cargo inspections on materials imported from these sources?

Which of the following is MOST likely to be an advantage of a standardization program?

Which of the following will likely offer the BEST incentive for a supplier to make continuous improvements in its supply chain performance?

Which of the following refers to a computer-based system that determines the purchase requisition requirements that go into the manufacture of end items, and addresses an organization's operational, financial and marketing strategies?

A manufacturing firm redesigns its premier product to benefit from material standardization. The change will entail re-tooling costs. The firm conducts a cost benefit analysis on four possible options. Option 1 is to make no change at all. Options 2, 3, and 4 represent different re-tooling configurations involving different materials:

Option 1Option 2Option 3Option 4

Re-tooling Costs (Year 1)$0$800,000$1,000,000$1,200,000

Material Costs

Year 151,000,000$700,000$650,000$600,000

Year 2$1,100,000$750,000$700,000$650,000

Year 3SI,200,000$800,000$750,000$700,000

Year 451,300,000$850,000$800,000$750,000

Year 551,400,000$900,000$850,000$800,000

Total$6,000,000$4,000,000$3,750,000$3,500,000

Labor Costs

Year 1$1,000,000$700,000$650,000$600,000

Year 2$1,100,000$770,000$715,000S660,000

Year 3$1,210,000$847,000$786,500$726,000

Year 4$1,331,000$931,700$865,150$798,600

Year 5$1,464,100$1,024,870$951,665$878,460

Total$6,105,100$4,273,570$3,968,315$3,663,060

In addition to this, there will be a cost of $3.5 million in lost production during Year 1, should any of the re-tooling options (2, 3, or 4) be selected.

The firm wants to rank the options in order of financial preference, from the best option to the worst. Based on this information, how should the four options be ranked?

A manufacturer of gardening products has many international suppliers. Because of extended lead-times and logistical concerns, it is critical that the company provides accurate seasonal demand planning data to its suppliers. Given this situation, which of the following types of feedback from the supplier would be MOST critical to the manufacturer?

A firm collects the following forecasted and actual demand for a certain part:

PeriodForecastActual

KI30311

22531

32826

42520

What is the absolute value of the forecast error?

Through cycle counting, a supply manager learns that inventory inaccuracies are being caused by errors made when received goods are entered into the company's enterprise business system. Which of the following is the FIRST course of action the supply manager should take to reduce these inaccuracies?

FGH, Inc. is a beverage manufacturer. FGH is having difficulty coordinating daily delivery requirements of bottles from Supplier X. Delivery schedules are set weekly, but often need to be changed. However, the supplier has otherwise established itself as reliable. In the hope of speeding up the replenishment process and reducing coordination efforts, FGH is prepared to share production and inventory information with Supplier X. In this situation, which of the following should FGH implement with Supplier X?

PQR, Inc. produces office supplies for big box retailers. This is a highly competitive market and the requirement for maintaining a continuous inventory of product for retailers is a high priority for PQR. Recently, the firm experienced shipping delays from overseas suppliers. Which of the costs associated with shortages would be MOST critical for PQR?

Which of the following will be MOST useful for measuring service quality?

When an organization is devising a long-term forecast, consulting external sources of information is MOST useful

DEF, Inc. is in the ramp-up phase of a unique medical device. The device has a two-year life expectancy. The sales forecast for the ramp-up period is as follows:

MonthJulAugSepOctNovDecJanFeb

Unit Sales1001502006001,4002,2004,00010,000

Demand after February is expected to remain at 10,000 units per month for several months, then decrease gradually. The units are small, and thus maintaining an inventory of up to 10,000 units is possible.

There are only three suppliers capable of providing the specialized component critical to this product. The production capacities of these suppliers are as follows:

•Supplier X has a capacity of 500 units per month at a cost of S20 per unit, representing 80% of its total business

•Supplier Y has a capacity of 2,000 units per month at a cost of S2O.5O per unit, representing 50% of its total business

•Supplier Z has a capacity of 20,000 units per month at a cost of $20.70 per unit, representing 10% of its total business

Two of these companies—Supplier X and Supplier Y—are minority businesses.

Given this situation, DEF should contract with

An organization purchases material from several countries. These materials are assembled into products and sold in several other countries. This firm's product specifications will MOST likely reference

XYZ, Inc. has experienced a significant increase in the number of expedited orders with a key supplier over the last few months. In this situation, XYZ should

Which of the following refers to the exporting of a product by a country or company at a price that is lower in the foreign importing market than the price charged in the exporter's domestic market?

A firm hires a contractor to build a new warehouse. During construction, the firm decides it wants to modify the contract to add an office area to the facility. Which of the following is the BEST course of action for the firm to take in this situation?

A supply manager is analyzing potential costs associated with the raw materials needed for a new product launch. Tooling costs are known, but the range of forecasts for future sales—and therefore demand for materials-varies widely. Given these circumstances, the supply manager should consider using which of the following?

Which of the following refers to the percentage of order requirements met through stock that is present on the shelf?

A company saves packaging from incoming shipments and utilizes the cartons to sort parts and pad outgoing pallets. This can BEST be described as

An ERP purchasing module indicates a gross requirement of 100 units for part number A123. There is an open purchase order for 55 units. The item master for this supplier shows an order lot size of 30 units each. In this situation, how many units of this part will the exception report indicate should be ordered7

Which of the following refers to an agreement between a buyer and supplier in which vendor-owned inventory is stored on the buyer's floor until it is used in production?

The sourcing manager for a regional retail bakery chain reviews order quantities and stocking for perishable condiments on a quarterly basis. Which of the following factors should be the MOST critical consideration in this analysis?

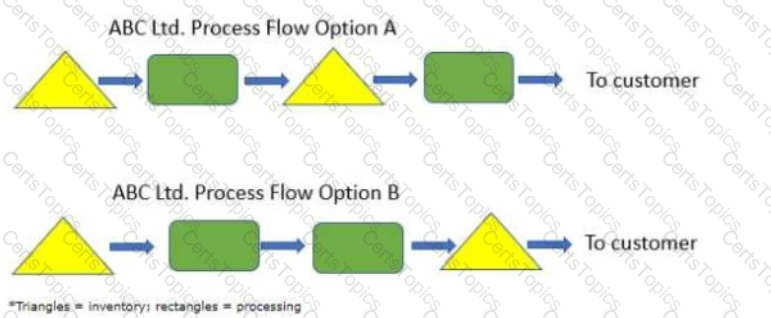

A firm has created the following process flow diagrams depicting two possible strategies for the production of a new product line. The triangles represent inventory, and the rectangles represent processing. Each of the two options start with the same raw materials, and both create the product through two stages of processing.

Which of the following statements is correct?

A manufacturer receives notice from one of its largest customers stating that, from this point on, it will only accept environmentally friendly boxes for packaging. The manufacturer checks the remaining packaging in its inventory and finds that it still has over six months' worth of boxes that are not made of environmentally-friendly materials. These boxes are custom-designed and cannot be returned to the packaging material supplier. In this situation, the manufacturer would be BEST served by doing which of the following?

Which of the following refers to the practice of buying a commodity on the open market for immediate delivery?