Verified By IT Certified Experts

CertsTopics.com Certified Safe Files

Up-To-Date Exam Study Material

99.5% High Success Pass Rate

100% Accurate Answers

Instant Downloads

Exam Questions And Answers PDF

Try Demo Before You Buy

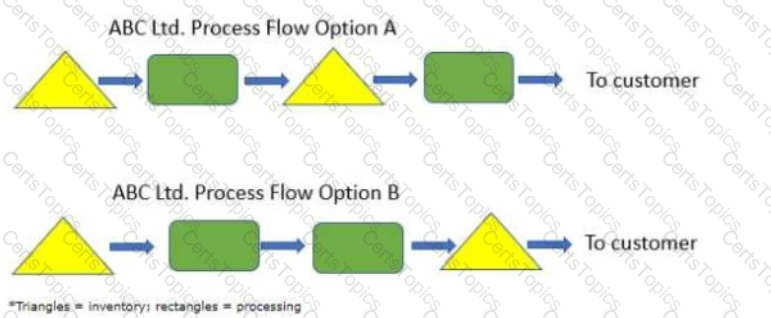

A firm has created the following process flow diagrams depicting two possible strategies for the production of a new product line. The triangles represent inventory, and the rectangles represent processing. Each of the two options start with the same raw materials, and both create the product through two stages of processing.

Which of the following statements is correct?

A company finds that delays and cost overruns are creating problems in its service contracts. To improve this situation, which of the following should the firm do FIRST?

A manufacturer is working to standardize high-volume, low-cost hardware components used in its assembly process. The manufacturer wants to transfer some of the risks associated with inventory carrying costs, warehousing costs, and re-stocking costs to the supplier. Which of the following will be MOST useful in accomplishing this goal?